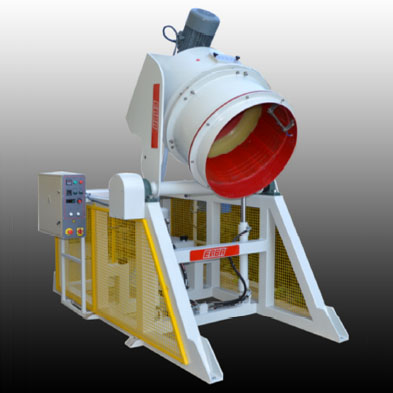

In a centrifugal tumbling machine, the movement of the abrasive media is created by means of a rotating disk at the bottom of the container. When the bottom disk is rotated, a drum-like movement is created in the machine and the tumbling mass is continuously thrown out against the walls of the working container where a high grinding pressure is created. Centrifugal tumbling is about 10-20 times more efficient than vibratory tumbling.

Characteristics of the machine type are: Very short tumbling time for small and medium-sized workpieces.

About 10-20 times faster than vibration tumbling.

Suitable for small to medium-sized parts with coarse burrs and high surface requirements. Rubber parts such as O-rings, small plastic parts etc.

Speed control with frequency converter.

Digital process timer.

Digital speed indicator.

Available in sizes from 9 liters up to 450 liters with different separation options and degree of automation.

Very short finishing time for small and medium-sized workpieces…

Centrifugal machines built according to a modular concept. The equipment can be equipped in many configurations. Available also withZero-gap for thin parts processing.

Centrifugal machines in a more basic design and with standardized accessories. Avalable also with zero-gap for thin parts processing.

© Trumlingsaktiebolaget 2024 | trumlings@trumlings.se | Åldermansvägen 1, SE 171 48 SOLNA | 08-446 60 10