The quality of punching, forming and cutting tools can be significantly improved by machining them with a drag finishing process. A defined edge rounding provides an increased service life for cutting tools such as carbide drills, taps, indexable inserts, small reamers, etc.

Drag finishing is also used to polish tools both before and after coating. When coating, so-called “droplets” are formed. A quick polishing process after coating of cutting tools gives a smoother surface finish and removes droplets, resulting in less friction and reduced wear of the tool.

Tool holders can also be polished to obtain a product with a more attractive appearance and to minimize the risk of corrosion.

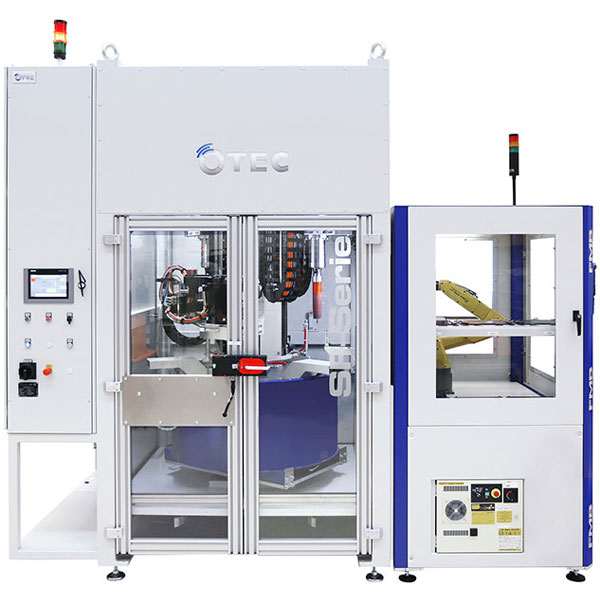

Stream finish machines for manual or automatic operation. Can be used for deburring, polishing, edge preparation or other surface improvement.

Machine specially designed for edge preparation of cutting tools, available in versions for up to 24 spindles.

Machine specially designed for edge preparation of cutting tools, available in versions for up to 36 spindles.

© Trumlingsaktiebolaget 2024 | trumlings@trumlings.se | Åldermansvägen 1, SE 171 48 SOLNA | 08-446 60 10